Artificial Intelligence in Manufacturing: Revolutionizing Predictive Maintenance Solutions

In the rapidly evolving landscape of modern industry, the ability to anticipate and prevent equipment failures is no longer a luxury but a critical necessity. Artificial intelligence in manufacturing predictive maintenance solutions is at the forefront of this transformation, offering unprecedented capabilities to enhance operational efficiency, reduce downtime, and significantly lower maintenance costs. This comprehensive guide delves into how cutting-edge AI and machine learning technologies are reshaping traditional maintenance strategies, moving industries from reactive fixes to proactive, data-driven interventions. Discover how the integration of AI can unlock the full potential of your industrial assets, ensuring peak performance and sustainable growth in the era of Industry 4.0.

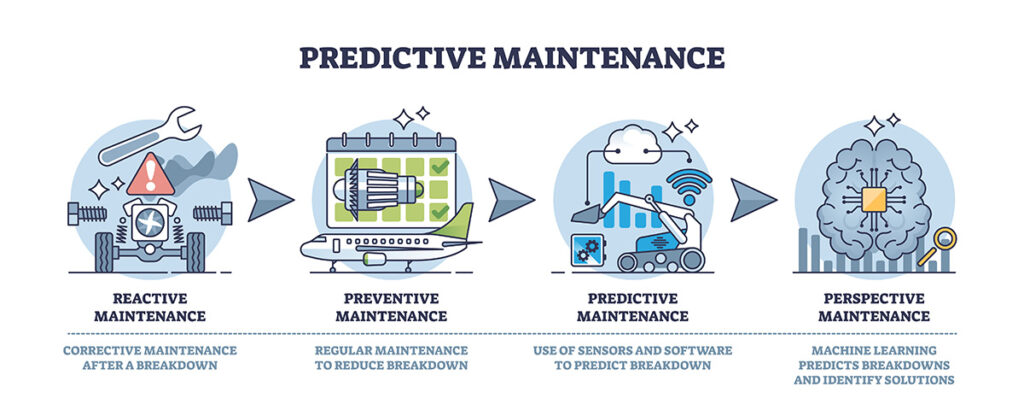

The Evolution of Maintenance: From Reactive to Predictive with AI

For decades, manufacturing maintenance largely followed a reactive or preventive approach. Reactive maintenance, often termed "run-to-failure," involved fixing equipment only after it broke down, leading to costly unplanned downtime and significant production losses. Preventive maintenance, a step forward, introduced scheduled inspections and servicing based on time or usage, aiming to prevent failures. While better, it often resulted in unnecessary maintenance on healthy equipment or missed issues that arose between scheduled checks.

The advent of Industry 4.0 and the proliferation of connected devices, often referred to as the Industrial IoT (IIoT), paved the way for predictive maintenance. This methodology uses real-time data to monitor asset health and predict potential failures before they occur. However, the sheer volume and velocity of sensor data generated by modern machinery presented a new challenge: how to effectively process and derive actionable insights from it. This is precisely where artificial intelligence in manufacturing predictive maintenance solutions becomes the game-changer.

AI, particularly machine learning and deep learning algorithms, possesses the unparalleled ability to analyze vast datasets, identify subtle patterns, and make highly accurate predictions about future equipment behavior. By leveraging AI, manufacturers can move beyond simple threshold-based alerts to truly intelligent, context-aware maintenance scheduling, transforming their operations into more agile and resilient systems.

How Artificial Intelligence Powers Predictive Maintenance in Manufacturing

The core strength of AI-driven predictive maintenance lies in its capacity to transform raw data into actionable intelligence. This process involves several critical stages, each powered by sophisticated AI techniques.

Data Collection and Integration

- IoT Sensors and Industrial IoT (IIoT): The foundation of any predictive maintenance system is robust data collection. Modern manufacturing equipment is increasingly outfitted with an array of IoT sensors that continuously monitor critical parameters such as vibration, temperature, pressure, current, acoustics, and oil quality. These sensors provide a constant stream of real-time data from various components.

- Historical Data Accumulation: Beyond live sensor feeds, historical data—including past maintenance records, repair logs, operational conditions, and environmental factors—is crucial. This extensive dataset provides the context for AI models to learn from past failures and successes.

- Data Aggregation and Pre-processing: All this disparate data, often coming from different systems (SCADA, MES, ERP), needs to be collected, integrated, cleaned, and normalized. This crucial pre-processing step ensures data quality and prepares it for effective analysis by AI algorithms.

Machine Learning Algorithms at Work

Once the data is ready, machine learning models take over. These algorithms are trained on the collected data to learn the normal operating patterns of machinery and identify deviations that indicate impending issues.

- Anomaly Detection: AI models are exceptionally skilled at identifying anomalies or unusual patterns in sensor data that deviate from normal operating conditions. These subtle shifts often precede major equipment failure. For instance, a slight increase in vibration frequency or an abnormal temperature spike might be flagged as an early warning sign.

- Pattern Recognition: Beyond simple anomalies, AI can recognize complex patterns that correlate with specific types of failures. For example, a combination of slight temperature fluctuations and increased power consumption over a specific period might indicate bearing wear.

- Predictive Modeling: Utilizing techniques like regression analysis, classification, and neural networks (a form of deep learning), AI models can predict the probability of failure and estimate the remaining useful life (RUL) of an asset. This allows maintenance teams to schedule interventions precisely when needed, avoiding both premature maintenance and catastrophic breakdowns.

Predictive Analytics and Insights Generation

The output of the machine learning models is then translated into actionable insights presented through intuitive dashboards and alert systems.

- Failure Prediction and Diagnostics: The system provides clear alerts about potential failures, often specifying the likely component at risk and the predicted timeframe. Some advanced systems even offer diagnostic insights into the root cause.

- Prescriptive Maintenance Recommendations: Moving beyond just predicting, AI can recommend the optimal course of action. This might include specific repair procedures, recommended spare parts, or even adjustments to operational parameters to extend asset life. This is often referred to as prescriptive maintenance.

- Visualization Dashboards: Maintenance managers and operators gain access to real-time dashboards that visualize asset health, performance trends, and upcoming maintenance requirements. This empowers them with the information needed for proactive decision-making.

Key Benefits of Implementing AI-Driven Predictive Maintenance Solutions

The adoption of artificial intelligence in manufacturing predictive maintenance solutions delivers a multitude of tangible benefits that directly impact a manufacturer's bottom line and operational resilience.

Drastically Reducing Downtime and Production Losses

One of the most significant advantages is the dramatic reduction in unplanned downtime. By predicting equipment failure with high accuracy, maintenance can be scheduled during planned outages or at times that minimize disruption to production. This directly translates to:

- Enhanced Operational Efficiency: Consistent production flow with fewer interruptions.

- Increased Throughput: More operational hours mean higher output capacity.

- Improved Delivery Times: Reliable production schedules lead to better customer satisfaction.

Optimizing Maintenance Costs and Resource Allocation

AI-powered predictive maintenance shifts the focus from reactive, emergency repairs—which are typically more expensive—to planned, efficient interventions. This results in substantial cost savings:

- Reduced Maintenance Costs: Eliminating unnecessary preventive maintenance and avoiding costly emergency repairs.

- Optimized Spare Parts Inventory: Knowing exactly when a part might fail allows for just-in-time ordering, reducing the need for large, expensive inventories.

- Efficient Workforce Management: Maintenance crews can be deployed strategically, performing work when it's genuinely needed, improving their productivity and reducing overtime.

Enhancing Equipment Lifespan and Performance

Proactive intervention based on AI insights helps in maintaining machinery in optimal condition, extending its operational life.

- Proactive Intervention: Addressing minor issues before they escalate into major problems, preserving asset health.

- Better Asset Performance Management: Continuous monitoring and optimization ensure that machinery operates at its peak efficiency, maximizing output and quality.

Improving Safety and Environmental Compliance

Preventing catastrophic equipment failures significantly enhances workplace safety by reducing the risk of accidents caused by sudden breakdowns. Furthermore, optimizing equipment performance can lead to reduced energy consumption and waste, contributing to environmental sustainability.

Practical Implementation Steps for AI Predictive Maintenance

Implementing an artificial intelligence in manufacturing predictive maintenance solution requires a structured approach. It's not just about installing software; it's about integrating technology, processes, and people.

1. Assessing Current Infrastructure and Data Readiness

Before diving in, evaluate your existing machinery, sensor deployment, and data collection capabilities. Do you have sufficient IoT sensors on critical assets? Is your data quality high enough? Where are your data gaps? This initial assessment will help define the scope of your project and identify necessary upgrades.

2. Pilot Project and Scalable Deployment

Start small. Select a critical piece of equipment or a production line for a pilot project. This allows you to test the AI solution, demonstrate tangible ROI, and refine your approach before a full-scale rollout. Once the pilot is successful, establish a phased deployment plan for broader adoption across your facility or organization.

3. Selecting the Right Technology and Partners

The market offers various AI platforms and software vendors specializing in predictive maintenance. Look for solutions that offer robust data ingestion capabilities, a variety of machine learning algorithms, intuitive visualization tools, and seamless integration with your existing enterprise systems (ERP, CMMS). Consider partnering with experts who can guide you through the implementation and customization process.

4. Building an Internal Data Science and Maintenance Team

Successful AI adoption requires a skilled workforce. Invest in training your maintenance engineers and technicians on how to interpret AI-generated insights and act on them. Consider hiring or upskilling data scientists who can manage and refine the AI models. Fostering collaboration between IT, operations, and maintenance teams is paramount for long-term success.

5. Continuous Improvement and Model Refinement

AI models are not static. They require continuous monitoring, evaluation, and refinement. As new data becomes available and operational conditions change, the models need to be retrained and updated to maintain their accuracy and effectiveness. This iterative process ensures the AI solution remains highly valuable over time.

Challenges and Considerations in Adopting AI Predictive Maintenance

While the benefits are compelling, manufacturers should be aware of potential hurdles when adopting artificial intelligence in manufacturing predictive maintenance solutions.

- Data Quality and Quantity: Poor data quality (incomplete, inaccurate, inconsistent) can severely hamper the effectiveness of AI models. Ensuring a continuous flow of clean, relevant data is a significant challenge for many organizations.

- Integration Complexity: Integrating new AI systems with legacy IT and operational technology (OT) systems can be complex and time-consuming.

- Cybersecurity Concerns: Connecting more devices to the network increases the attack surface. Robust cybersecurity measures are essential to protect sensitive operational data.

- Skilled Personnel Shortage: A lack of internal expertise in data science, AI, and IIoT can impede successful implementation and ongoing management.

- Resistance to Change: Employees accustomed to traditional maintenance practices may resist new AI-driven workflows. Effective change management and training are crucial.

- Cost of Initial Investment: While the ROI is significant, the initial investment in sensors, software, and training can be substantial.

The Future of AI in Manufacturing Maintenance: Beyond Predictive

The journey of artificial intelligence in manufacturing predictive maintenance solutions is far from over; it's continuously evolving. We are already seeing advancements that push the boundaries beyond mere prediction:

- Digital Twin Integration: The integration of AI with digital twin technology creates virtual replicas of physical assets. These digital twins can simulate various scenarios, test maintenance strategies, and predict behavior with even greater accuracy, leading to highly optimized asset performance management.

- Autonomous Maintenance: In the long term, AI could enable machines to self-diagnose, self-heal, and even order their own spare parts, ushering in an era of truly autonomous maintenance operations.

- Hyper-Personalization of Maintenance: AI will allow for maintenance schedules and procedures to be tailored not just to machine type, but to the unique operational history and current condition of individual assets, maximizing their uptime and lifespan.

- Prescriptive and Adaptive Maintenance: AI's ability to not only predict but also prescribe specific actions and adapt to changing conditions will become increasingly sophisticated, offering real-time, dynamic maintenance strategies.

Embracing AI in predictive maintenance is not just about adopting new technology; it's about fundamentally rethinking how manufacturing operations are managed. It's an investment in resilience, efficiency, and future competitiveness. For manufacturers looking to gain a significant edge in today's demanding market, exploring and implementing these intelligent solutions is a strategic imperative.

Frequently Asked Questions

What is the core difference between preventive and predictive maintenance with AI?

The core difference lies in their approach to scheduling. Preventive maintenance is time-based or usage-based, meaning maintenance is performed at fixed intervals or after a certain number of operating hours, regardless of the equipment's actual condition. In contrast, predictive maintenance with AI uses real-time data from IoT sensors and machine learning algorithms to anticipate equipment failure before it happens. This allows maintenance to be scheduled only when it's truly needed, optimizing resources and preventing unnecessary downtime. AI provides the intelligence to accurately predict the "when" and "what" of a potential failure.

How do IoT sensors contribute to AI predictive maintenance?

IoT sensors are the eyes and ears of an AI predictive maintenance system. They continuously collect critical operational data such as vibration, temperature, pressure, acoustic emissions, and current draw from machinery. This sensor data is fed to AI and machine learning algorithms. The AI then analyzes this real-time data, alongside historical data, to identify subtle anomalies or patterns that indicate potential issues. Without this continuous stream of precise data from industrial IoT devices, AI models would lack the necessary input to make accurate predictions about equipment health and impending failures.

What kind of data is crucial for AI-powered predictive maintenance solutions?

For effective AI in manufacturing predictive maintenance solutions, several types of data are crucial. Primarily, this includes real-time sensor data (vibration, temperature, current, pressure, etc.) from machines. Equally important is historical data, which encompasses past maintenance records (repair dates, types of repairs, parts replaced), operational parameters (production rates, load, speed), environmental conditions (humidity, ambient temperature), and even machine specifications. The combination of live and historical data allows AI models to learn normal operating baselines, identify deviations, and predict future failures based on past patterns and outcomes. Data analytics plays a key role in processing these diverse data streams.

Is AI predictive maintenance only for large manufacturers?

While large manufacturers often have the resources to implement comprehensive artificial intelligence in manufacturing predictive maintenance solutions, the technology is becoming increasingly accessible for small and medium-sized enterprises (SMEs) as well. The rise of cloud-based AI platforms, more affordable IoT sensors, and scalable solutions means that even smaller operations can benefit. Starting with a pilot project on a few critical assets can demonstrate ROI and justify broader implementation. The benefits of reduced downtime and optimized costs are universal, regardless of company size.

What are the typical ROI metrics for AI in predictive maintenance?

The Return on Investment (ROI) for AI in manufacturing predictive maintenance solutions is typically measured through several key metrics. These include a significant reduction in unplanned downtime (often 20-50%), a decrease in maintenance costs (10-40% by shifting from reactive to proactive repairs), extended asset lifespan (up to 20%), optimized spare parts inventory (reducing carrying costs), and improved operational efficiency. Additionally, there are often intangible benefits such as enhanced safety, better product quality due to consistent machine performance, and improved worker morale. Many companies report payback periods of less than 1-2 years due to these substantial savings and efficiency gains.

0 Komentar